Why The Design And Construction Of Joints Are So Important In Concrete Structures Minni

Reinforced concrete must be designed and constructed to accommodate the inevitable movements which will take place: • Shrinkage - Initially rapid, less severe as the concrete ages. • Creep - A phenomenon which causes a redistribution of stress away from points of intensity. • Thermal movement - Expansion and contraction of the structure.

Concrete Joint Section Repair USAR

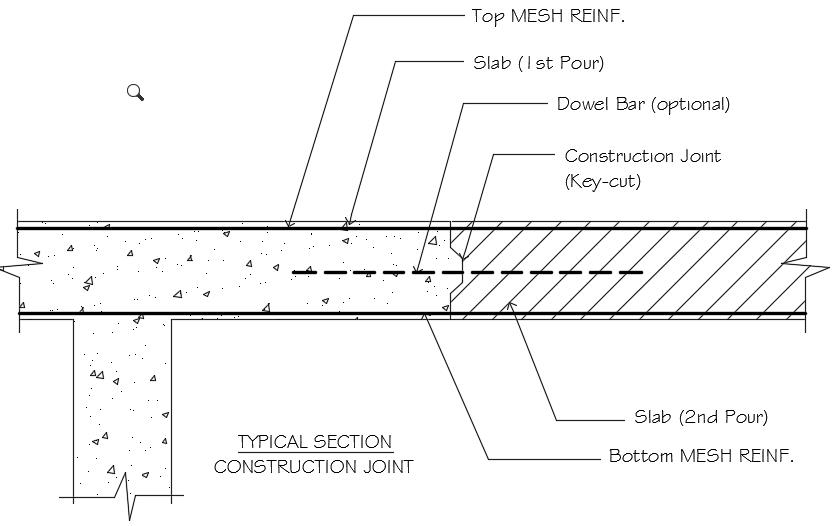

Here are a few tips: Construction joints are formed using some sort of bulkhead, made of wood, steel, plastic, or precast concrete. These bulkheads are often used as screed rails during placement and finishing of the slab. Construction joints should be worked into the overall joint plan, where they can also function as contraction joints.

Construction Joint or Daywork Joint Connecting Concrete Pours Successful Joints CivilDigital

Contraction joints may be tooled into the concrete surface at the time of placement. Joints may be tooled into the surface (first pass) prior to the onset of bleeding or immediately with the first pass of the floating operation. The longer the first pass for jointing is delayed the more difficult it will be to shape clean straight line joints.

Movement Joints In Concrete Floor Slabs Carpet Vidalondon

Contraction Joints A contraction joint is a sawed, formed, or tooled groove in a concrete slab that creates a weakened vertical plane. It regulates the location of the cracking caused by dimensional changes in the slab.

Types and Advantages of Construction Joint Civil Snapshot

A concrete expansion joint - or control joint - is a gap which allows the concrete to expand and contract as/when the temperature changes. It forms a break between the concrete and other parts of a structure to allow movement without causing stress, which can lead to cracking.

Types of Construction Joints in Concrete Engineering Feed

Joints are necessary in concrete structures for a variety of reasons. Not all concrete in a given structure can be placed continuously, so there are construction joints that allow for work to be resumed after a period of time. Because concrete undergoes volume changes—principally related to shrinkage and temperature changes—it can be desirable to provide joints and, thus, relieve tensile.

Concrete Floor Slab Construction Joints Flooring Site

Providing construction joint in concrete limits the area to be concreted in a one pour. For example, when there is a large area to be concreted, we divide the area into several pours. It speeds up the construction work as part completion of work can proceed to concrete work. Further, a large area cannot be concreted within a day.

Construction Joint or Daywork Joint Connecting Concrete Pours Successful Joints CivilDigital

Shop Roof Repair Products And Other Construction Products At Toolstation. Find Incredible Deals On Hundreds Of Quality Trade Products At Toolstation.

Construction Joint in Concrete Types, Location Selection and Advantages

5.8 Construction joints and pour sizes 10 72 5.9 Water-resisting construction 10 73 Section 6 Reinforcement 11 74 6.1 Materials 11 74 6.2 Execution 13 77 Section 7 Prestressed concrete construction 14 78 7.1 Design and quality control 14 78 7.2 Materials 14 79 7.3 Execution 15 80 7.4 Records 17 82 Section 8 Concrete and concreting 18 82

Construction Joint In Road Polymer concrete expansion joint ROBOSTATIFLEX Mageba A

Types of joints in concrete. Mainly, there are four types of joints in concrete: construction, isolation, expansion, and contraction joints. 1. Construction joints. A construction joint is basically an interface between two concrete pours, with a time interval longer than the initial setting time of the first.

Types of Construction Joints in Concrete BN Products

Construction Joints Introduction: Any concrete structure that is going to require numerous movement joints, is best designed by a civil or structural engineer. All concrete, once placed, will contract slightly during the curing process; this is the primary cause of small surface cracks that appear during the curing process.

Settlement Joints Building & Construction, Civil Engineering & Structural Designs November 2023

The resultant contact surface is known as a construction joint or daywork joint. Such joints must be formed carefully so that they transmit the required forces and, where appropriate, do not leak. Firstly the surface of the hardened concrete must be clean and free from laitance (the relatively soft surface layer) and any dust or debris.

Construction Joint in Slabs The Structural World

Contraction Joints Placing Joints Sealing Joints Different joints in concrete slabs all have the same bottom-line purpose of preventing cracks. The Purpose of Joints in Concrete Slabs As concrete moves, if it is tied to another structure or even to itself, we get what's called restraint, which causes tensile forces and invariably leads to cracking.

meat first part of floor complete

INTRODUCTION. This CPD module will outline the types of joints involved in building and civil engineering structures and will look at technical issues facing contractors and maintenance personnel. There are three basic types of joints: Construction joints - typically the daywork joints in concrete, where one pour or day's work ends and.

Types of Concrete Joints in Buildings Civil Snapshot

Construction joints are designed in order to allow the displacement between each (both) sides of the slab but, they also transfer the flexural stresses produced in the slab by the external loads at the same time. Construction Joint in Concrete: Exploring Types of Construction Joints, Including Contraction Joints and Expansion Joints 12

Concrete Construction Joint at Construction Site. Stock Image Image of mesh, contractor 80766843

When joint pain flares choose Flarin Joint & Muscular Pain Relief,. For joint pain relief as effective as prescription strength ibuprofen, choose Flarin